SHAFT ALIGNMENT METHODS:

There are three methods of coupling alignment:

1.

Straight edge& feeler gauge

2. Dial

indicators:

Single

dial method

Double

dial method

3. Laser

alignment

COUPLING ALIGNMENT PROCEDURE:

- Coupling alignment involves following steps:

- Ends float assessment and arrest.

- Diagonal Checking for leveling of the equipment on bed.

- Vertical Angular misalignment correction.

- Vertical Offset misalignment correction.

- Horizontal Angular misalignment correction.

- Horizontal Offset misalignment correction.

- Final horizontal angular and offset misalignment correction.

CHECKING SHAFT RELATED RUN OUT:

“TIR” should not exceed 0.025mm per 50mm distance from

bearing”

LEVEL CHECKING: Done for

elimination of clearance between feet of driver and bed.

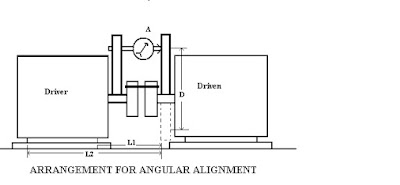

ANGULAR MISALIGNMENT CHECKING:

ANGULAR MISALIGNMENT CHECKING:

Misalignment Existing:

•

At Inboard = L1 / D x A

•

At Outboard = L2 / D x A

L1 = Inboard distance from pivot point in

mm

L2 = Outboard distance from pivot point

in mm

D = Pivot point diameter

A = Net misalignment reading in mm.

Net misalignment = ( L2 - L1

) X A / D

(Add shims at Inboard or outboard depending upon inclination

of the driver)

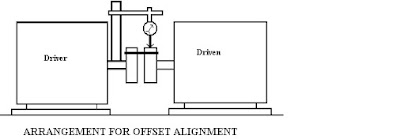

OFFSET MISALIGNMENT CHECKING:

Shims to be added at all the 4 base bolts = TIR / 2

CORRECTION METHOD OF HORIZONTAL OFFSET

MISALIGNMENT:

HORIZONTAL ANGULAR MISALIGNMENT

CORRECTION METHOD:

SHIM INSTALLATION AT REAR FOOT OF MOTOR:

SHIM INSTALLATION AT FRONT FOOT OF MOTOR:

ALIGNMENT CORRECTION WITH FEELER GAUGE

AND SCALE:

VERTICAL PUMP ALIGNMENT:

SHIMS:

- Try to use a maximum of 4 or less shims under each foot.

- It’s not always possible, but tries to minimize the number of shims per foot.

- Use pre-cut stainless steel shims. You can’t cut them for less than you can buy them.

- When you insert shims under the foot, slide them all the way in, then back them out 5mm, so the bolt threads don’t bend them.

- Don’t reuse painted or badly bent shims.

- Be careful. A 0.05mm shim can cut you like a knife.

- Keep them neat.

DIAL INDICATORS: